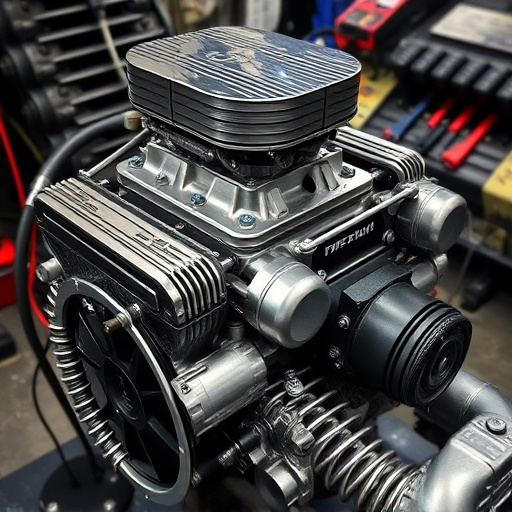

Dyno tuning is a crucial process for optimizing engine performance and preventing detonation (knocking), a harmful issue that can damage critical components. Using a dynamometer (dyno), mechanics fine-tune parameters like timing, fuel delivery, and compression ratios to ensure safe and efficient operation. This method enhances power output while reducing the risk of component failure, especially important for modified vehicles. By improving fuel-air ratios and ignition timing, dyno tuning contributes to overall engine health, reliability, and longevity, making it a best practice in high-performance automotive maintenance.

Dyno tuning is a powerful tool for optimizing engine performance while ensuring stability. In this article, we explore how dyno tuning helps prevent two common issues: detonation and engine knock. By understanding these phenomena, we delve into the science behind dyno tuning and its pivotal role in enhancing engine longevity and efficiency. We also highlight the benefits and best practices associated with dyno tuning to help enthusiasts achieve peak engine performance safely.

- Understanding Engine Detonation and Knock

- The Role of Dyno Tuning in Prevention

- Benefits and Best Practices for Dyno Tuning

Understanding Engine Detonation and Knock

Engine detonation, also known as “knocking,” is a common issue that can significantly impact an engine’s performance and longevity. It occurs when the air-fuel mixture inside the cylinder ignites prematurely, leading to unwanted pinging or knocking sounds. This phenomenon can cause serious damage to vital components like pistons, valves, and the cylinder wall due to the extreme pressure and temperature fluctuations it generates.

Dyno tuning plays a pivotal role in preventing detonation and knock by carefully optimizing various engine parameters. Through controlled testing on a dynamometer (dyno), mechanics can identify issues with timing, fuel delivery, compression ratios, and more. By adjusting these factors, they ensure the engine operates within optimal conditions, maximizing power output while minimizing the risk of damaging components often associated with detonation. Additionally, upgrades like high-performance brake pads and a performance exhaust system, though not direct solutions to knocking, can contribute to overall engine health by enhancing braking efficiency and improving exhaust flow, respectively.

The Role of Dyno Tuning in Prevention

Dyno tuning plays a pivotal role in preventing detonation and engine knock, two common issues that can severely damage an engine if left unchecked. By utilizing advanced diagnostic tools on a dynamometer (dyno), tuners can precisely measure and adjust various parameters to optimize engine performance. This process involves tweaking fuel-air ratios, ignition timing, and compression ratios to ensure the engine operates smoothly under all conditions.

In many cases, installation of modifications like cold air intakes, exhaust tips, or suspension kits can alter an engine’s behavior. Dyno tuning helps counteract these changes, fine-tuning the system to maintain stable power output and prevent unwanted detonation events. This is particularly crucial for high-performance vehicles where pushing engine limits is common, ensuring that power gains are achieved without sacrificing reliability or longevity of the engine.

Benefits and Best Practices for Dyno Tuning

Dyno tuning is a powerful tool for fine-tuning an engine’s performance and stability. By utilizing a dynamometer (dyno), mechanics can precisely measure and analyze various factors such as power output, torque, and fuel efficiency. This process helps identify issues like detonation and engine knock, enabling the adjustment of critical components to achieve optimal performance. One of the key benefits is its ability to prevent premature wear and tear on engines by setting ideal operating parameters, ensuring longevity and reliability.

When practicing dyno tuning, several best practices should be followed for accurate results. First, ensure proper preparation of the vehicle, including a clean engine bay and secure mounting of sensors. Next, focus on critical components like cold air intakes, which can significantly impact airflow and power output. Adjusting intake systems to match exhaust setups with performance exhaust and strategically placed exhaust tips can enhance overall efficiency. Additionally, maintaining a controlled environment during dyno tuning minimizes variables, allowing for more precise tuning. This meticulous approach ensures that adjustments are tailored to the vehicle’s specific needs, maximizing its potential without compromising safety or reliability.

Dyno tuning is a powerful tool for preventing engine detonation and knock, ensuring optimal performance and longevity. By fine-tuning the engine’s parameters on a dynamometer, professionals can identify and rectify issues before they cause damage. This process offers numerous benefits, including improved fuel efficiency, increased horsepower, and enhanced overall engine health. Adhering to best practices, such as using high-quality equipment and data analysis, ensures that dyno tuning delivers precise results, making it an indispensable practice for automotive enthusiasts and professionals alike.